Guidance for Regulatory Compliance of Recycled Plastics for Food Packaging in the U.S.

Overview

Navigating U.S. FDA legal requirements for recycled plastics in food packaging is crucial for registration and market access. While obtaining a No Objection Letter (NOL) is voluntary, it validates your recycling process. We simplify the process, covering who can apply, recycling methods (primary, secondary, tertiary), and data requirements for food-contact scenarios. It’s a must-read for manufacturers and exporters aiming for regulatory compliance and industry recognition.

Background: U.S. Regulations on Food-Contact Recycled Plastics

The United States permits the use of recycled plastics in food packaging, with oversight conducted by the U.S. Food and Drug Administration (FDA). The Office of Food Additive Safety (OFAS) under the FDA is responsible for evaluating specific recycled plastic processes. The regulations and guidance documents that specifically manage and guide the compliant use of recycled plastics in food packaging include:

-

Federal Regulation: Federal Food, Drug, and Cosmetic Act (FD&C Act)

-

Federal Regulation: Code of Federal Regulations Title 21 (21 CFR)

No Objection Letter (NOL)

In the United States, the registration of recycled plastics for food contact applications typically refers to manufacturers requesting a No Objection Letter (NOL) from the U.S. FDA. Although obtaining NOL is not legally mandated under U.S. regulations, this letter can be regarded as a positive evaluation of the FDA on its recycling process. It has a high degree of recognition within the recycled plastics industry. For enterprises exporting recycled plastic products to the US market, it is strongly recommended to proactively apply for a No Objection Letter (NOL) from the FDA.

Who May Apply for NOL

-

Recycled Plastics Manufacturer

-

Recycled Plastics Equipment Manufacturer

-

Recycled Plastics User (can be submitted jointly with the Recycled Plastics Manufacturer)

If a recycled plastics equipment manufacturer obtains a NOL from the FDA, downstream manufacturers who purchase the certified equipment and receive a sublicense do not need to request a new NOL issued to their name, as long as the recycling process and intended use conditions of recycled plastic are exactly the same as described in the original applied NOL.

Recycling Processes

Primary Recycling

The process involves using scraps generated during the production of food contact products as raw materials and recycling them within a closed-loop system. Under the premise of complying with good manufacturing practices, these scraps are reprocessed into food packaging.

Secondary Recycling

Also known as Physical Recycling, which involves mechanical processing of recycled plastics through grinding, melting, extrusion, and other physical methods. This process aims to remove residual contaminants from the feedstock while ensuring that the polymer composition and structure of the reprocessed plastics remain unchanged.

Tertiary Recycling

Also known as Chemical Recycling, refers to a process that involves chemically decomposing recycled materials into monomers or oligomers, followed by refining, distillation, and purification to remove residual contaminants. The purified monomers are then repolymerized through chemical reactions to produce new plastic pellets.

The above three recycling processes can all apply for a No Objection Letter (NOL) from the FDA.

NOL Application Data Requirement

NOL application data requirements differ according to the use of recycled plastics in food packaging in different scenarios.

Specific Intended Use: Recycled food contact plastics are used in contact with Food Type VIII, including raw fruits, vegetables, and shell eggs, under the condition of room temperature or refrigerated storage.

Data requirement: Recycling process description, intended use description, and compliance test report.

General Intended Use: Recycled food contact plastics are used in contact with all types of food and their use condition may involve high temperature sterilization.

Data requirement: Recycling process description, intended use description, compliance test report, and surrogate contaminant testing report.

Surrogate Contaminant Testing Report: conduct surrogate contaminant testing (commonly called challenge test) to verify whether the recycling process achieves sufficient decontamination capability. This requirement applies to secondary (physical) recycling and tertiary (chemical) recycling processes, while the primary recycling process is exempt from this requirement.

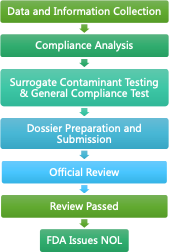

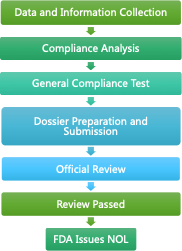

Application Workflow

General Intended Use Application

Specific Intended Use Application

REACH24H’s Services

-

Pre-application Regulatory Compliance Analysis

-

General Intended Use NOL Application(Surrogate Contaminant Testing involved)

-

Specific Intended Use NOL Application

-

Primary Recycling NOL Application

-

Surrogate Contaminant Testing Supervision

-

FDA Official Communication and PNC Inquiry

-

Regulatory Information Update Service

REACH24H’s Strengths

-

Specialized in food contact material compliance and in-depth research in global mainstream regulations including China, U.S., EU, Canada, MERCOSUR, etc.

-

Proven success across all application types

-

Reliable laboratory resources for surrogate contaminant testing

-

Multinational team support, with subsidiaries in the U.S., the United Kingdom, Ireland, South Korea, Japan, and Singapore

Conclusion

The U.S. FDA permits the use of recycled plastics in food packaging, and obtaining a No Objection Letter (NOL) is a voluntary yet highly recognized step to validate recycling processes. Manufacturers and exporters are encouraged to apply for an NOL. REACH24H offers comprehensive and professional services for regulatory compliance of recycled plastics in food contact, helping businesses streamline market access.