A Guide to EU Regulations on Recycled Plastics for Food Contact

Overview

As a manufacturer, equipment supplier, or user of recycled plastics targeting the European market, what should you know about EU regulations on recycled plastics for food contact? How can you ensure regulatory compliance and smooth market access? This article dives deep into the EU regulations for food contact recycled plastics, focusing on the Scientific Opinion Letter (SOL) application, suitable recycling technologies, and the data requirements for compliance.

Regulatory Background on Recycled Plastics for Food Packaging

-

Framework Regulation for Food Contact Materials: Regulation (EC) 1935/2004

-

Monomers and additives used in recycled plastics must comply with Regulation (EU) 10/2011

-

Production of recycled plastics must adhere to Good Manufacturing Practice: Regulation (EC) No 2023/2006

Scientific Opinion Letter (SOL)

According to the Regulation (EU) 2022/1616 on recycled plastics, only recycled plastics produced using processes authorized by the European Food Safety Authority (EFSA) can be used for food contact applications. For companies exporting recycled plastic products to the EU market, Scientific Opinion Letter application is required (excluding closed-loop recycling processes). EFSA evaluates the compliance of recycled plastics based on the technology and processes used and issues a scientific opinion on the applied process. Once a positive SOL conclusion is obtained, the process is accepted by EFSA.

Who May Apply?

-

Recycled Plastics Manufacturer

-

Recycled Plastics Equipment Manufacturer

-

Recycled Plastics User (can be submitted jointly with the Recycled Plastics Manufacturer)

Suitable Recycling Technology

In the EU, a recycling process must first be recognized as a suitable recycling technology before it can proceed with EFSA registration. Currently, the suitable recycling technologies defined by the EU include:

-

Mechanical PET Recycling

-

Closed-loop Recycling

Among these, mechanical PET recycling technology requires EFSA to evaluate each individual recycling process. The PET recycled products obtained from mechanical recycling cannot be used for microwave heating and oven applications. Closed-loop recycling technology requires a complete recycling scheme and does not need to apply for individual process evaluation with EFSA. Any other recycling technologies are classified as “Novel Technology” and require a complex new technology application process to obtain EU approval before they can be applied.

Data Requirement

For PET Mechanical Recycling Technology, the required documentation includes incoming material information, a complete description of the decontamination process, challenge test report, and compliance test report.

Challenge Test: a specially designed test that uses chemical substances of different molecular weights and polarities to simulate all possible contaminants that may exist in the recycled material, demonstrating the decontamination efficiency of the recycling process.

Compliance Test: the test required under the EU Food Contact Plastics Regulation (EU) No. 10/2011. It includes specific migration test, overall migration test, heavy metal, and aromatic primary amine migration test.

For closed-loop recycling technology, the manager of the recycling system is required to set up a recycling scheme, which should include the name and members of the recycling system and describes the operation process of the recycling system. The closed-loop recycling system requires that the intended use of recycled materials shall be limited to the same purpose as before recycling.

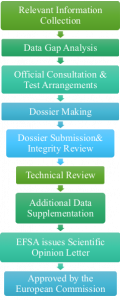

Application Workflow

What REACH24H Can Do for You?

-

Pre-application Regulatory Compliance Analysis

-

EFSA Scientific Opinion Letter Application

-

Challenge Test Supervision

-

EFSA Official Communication and Inquiry

-

Regulatory Information Update Service

What Sets REACH24H Apart?

-

Specialized in food contact material compliance and in-depth research in global mainstream regulations, including China, U.S., EU, Canada, MERCOSUR, etc.

-

Comprehensive expertise in regulatory compliance across European and American markets

-

Reliable laboratory resources with proven expertise in challenge test

-

Multinational team support, with subsidiaries in the U.S., the United Kingdom, Ireland, South Korea, Japan, and Singapore

Conclusion

Meeting EU regulations on recycled plastics for food contact is no small feat. You need to choose the right recycling technology, apply for SOLs, and stay updated on regulatory changes. The whole process demands expertise and precision. This is where REACH24H shines. As a global leader in regulatory compliance, we specialize in EU regulations on recycled plastics packaging in contact with food. Contact us today and take the first step toward seamless market access in the EU.

FAQ

1. What is the EU regulation for food contact materials?

Regulation (EC) No 1935/2004 establishes a harmonized EU legal framework, outlining the general principles of safety and inertness that apply to all Food Contact Materials (FCMs). This regulation ensures that materials intended for food contact do not compromise food safety or human health.

2. What is the EU 10/2011 regulation on plastic food contact materials?

Regulation (EU) 10/2011 establishes safety requirements for plastic materials and articles that are designed to come into contact with food. This regulation is a specific measure for plastic food contact materials as mentioned in the European Framework Regulation (EU) 1935/2004.

3. What does closed-loop recycling mean?

Closed-loop recycling is a process that exclusively recycles plastics from entities engaged in closed cycles (manufacturing/distribution/catering) and participating in a certified recycling scheme.

Plastic input originates only from materials and articles that are intended and used for food contact. The scheme excludes the collection of materials and articles as plastic input if these have been provided to consumers for use outside of the premises and/or control of the entities participating in the recycling scheme.

The recycled plastic is used only for manufacturing plastic materials and articles for contact with the same foods and under the same conditions as the collected materials and articles were intended for, and for which compliance to Regulation (EU) No 10/2011 was initially verified.

4. What is Mechanical PET Recycling?

Mechanical PET recycling involves converting post-consumer PET plastic waste into new, usable materials by employing physical processes such as sorting, cleaning, shredding, melting, and extrusion, without altering the chemical structure of the polymer.